Slogan

Design and manufacture of machinery for the food industry

Water jet cutting

Nos conseillers sont là pour répondre à vos

questions et vous proposer la solution la plus

adaptée à vos besoins.

Démonstration en vidéo

Water jet cutter

- Sweet & savory pastry

- Fruits and vegetables

- cheese factory

- Fish

Type de machine

- Rotary table

- Flying tracking cutting

- With transfer/conveyor belt

- Product-friendly support

Caractéristiques techniques

Rotary table

- Cuts fresh or frozen products, sweet or savoury pastries, fruits, vegetables and fish,

- Cuts all products following standard, customised or event schemes,

- Cuts on product-friendly supports,

- Cuts with 1 or 2 cutting heads,

- Standard cutting area per rotary table: 600 x 400 mm

Flying tracking cutting

- Cuts all products following standard, customised or event schemes,

- Cuts the product while in motion,

- Cuts with 1 or several cutting heads depending on the pace and amount of pieces to produce

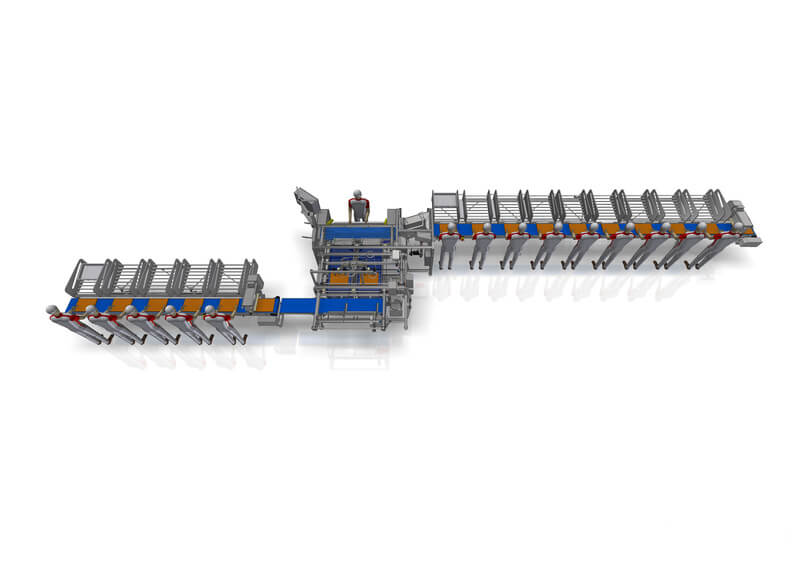

With transfer/conveyor belt

- Cuts all products following standard, customised or event schemes,

- Cuts on product-friendly supports,

- Cuts on standard supports,

- Ability to customise the cutting size

Product-friendly support

- Cuts on an adapted support to preserve the product

- Ability to use 1 or several cutting nozzles

- Ability to have interchangeable supports promptly

Avantages

Rotary table

- Simultaneous-tasking: while a product is being cut on the one rotary table, the operator loads and/or unloads the other so there is only one operator for two tasks

- Easy to clean

Flying tracking cutting

- Machine adaptable to the transfer and to the speed at which the products are conveyed

- Insertable on a production line

- Easy to clean

With transfer/conveyor belt

- Simultaneous-tasking: while a product is being cut on the one rotary table, the operator or an automatic system loads and/or unloads a product to cut on the other

- Easy to clean

Product-friendly support

- Simultaneous-tasking so there are significant productivity gains

- Supports can be designed for all types of products (meat, fish, fruits and vegetables, and sweet, savoury, fresh or frozen pastries...)

- Easy to clean